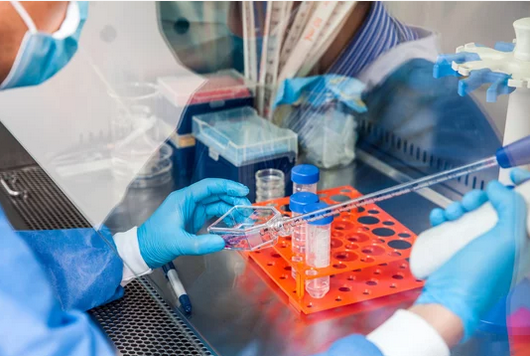

In most laboratories, a chemical fume hood is a piece of equipment that is installed to create a safe environment. Lab employees can work with hazardous chemicals in an enclosed space, safeguarding their wellbeing as well as others in the lab. Fume hoods are used to ensure a safe work environment. Fully understanding the importance of this piece of equipment can help laboratory employees stay safe and function properly.

Preventing Vapor Inhalation

The main reason why a fume hood is used in a laboratory is to stop the inhalation of toxic fumes. When employees breathe in hazardous fumes, it will cause the toxins to attach to the lungs or enter the bloodstream. Dizziness can occur as well as cause damage to other areas of the body. With a fume hood in place, dealing with volatile materials is safer, as the equipment creates a barrier between the harmful vapors and the lab personnel.

Ventilation

A fume hood that has been installed properly can provide localized ventilation for the space. There are different types of fume hoods that can be used, such as ducted or ductless models. A ducted hood will have ductwork attached to the hood that moves the dangerous vapors outside of the laboratory. A ductless hood will have filters that clean the exhaust air before recirculating it back into the laboratory space. It is important to install the appropriate fume hood that will function for the work being conducted in the lab.

Containing Spills

In a chemical fume hood, the work surface can contain spills. When it is properly functioning, and installed correctly, the unit will be able to contain any minor liquid spills. The hood will have a lip that will act as a catching area for spillages. This helps to protect other surfaces in the labs as spills will be limited to an enclosed space.

For the safety and integrity of the lab, lab fume hoods or several fume hoods should be installed, based on the size and workload of the laboratory. When extremely dangerous work must take place involving hazardous chemicals and other potential hazards, a fume hood is essential. This adequate form of protective equipment is needed so that lab personnel feel safe and secure when conducting experiments or testing.

When planning an installation, be sure to order the correct fume hood type, with proper ventilation methods and spill containment areas. With the proper setup, the fume hood will function for an extended period, protecting the hood user from harmful toxins and materials. To learn more about laboratory chemical fume hoods, give us a call today. Contact our team to find out the essential information on a new fume hood installation for your laboratory space or laboratory building.

FAQs

Fume hoods are designed to provide containment and ventilation for a wide range of hazardous chemicals, biological agents, and other dangerous fumes encountered in the laboratory. They allow lab personnel to safely handle volatile organic compounds, corrosive acids, and other irritating or toxic vapors. The level of protection provided by the fume hood depends on factors like the hood’s construction material (e.g. stainless steel), the type of filtration system, and the equipment’s overall performance. Proper use of a fume hood is a critical engineering control for mitigating exposure risks when working with hazardous materials.

Maintaining proper airflow and ventilation is essential for a fume hood to function as an effective safety device. This is typically measured by the hood’s face velocity, which should be within the recommended range, usually between 80-100 feet per minute (FPM). The presence of a magnehelic gauge or other hood performance indicator allows you to monitor the air velocity at the hood’s work opening. Additionally, the connected ductwork and exhaust fan must be properly sized and operating efficiently to pull contaminated air out of the workspace. Regular inspection and testing by maintenance personnel can verify the fume hood is providing adequate ventilation and containment of hazardous vapors.

While a properly functioning fume hood provides an important engineering control, it does not eliminate the need for appropriate personal protective equipment (PPE). When working with hazardous chemicals or other biohazardous material inside a fume hood, lab personnel should don impermeable gloves, a lab coat, and safety goggles at a minimum. In some cases, respiratory protection such as a respirator may also be required if the fume hood does not provide adequate containment on its own. The specific PPE needed will depend on the level of risk and health hazards associated with the materials being handled. Consulting safety guidelines and manufacturer recommendations can help determine the optimal personal protection when using a laboratory fume hood.

Regular cleaning and maintenance are crucial for ensuring a fume hood continues to function as a reliable safety device. This includes wiping down interior surfaces with appropriate cleaning agents to remove any chemical residue or particulate buildup. The hood’s baffles, fans, and ductwork should also be inspected and serviced per the manufacturer’s recommendations. Filters on ductless fume hoods need to be changed at the specified intervals to maintain their efficacy in trapping hazardous vapors. Additionally, the air velocity and overall hood performance should be tested periodically by qualified maintenance personnel. Proper upkeep helps maximize the fume hood’s containment capabilities and extends its useful life in the laboratory.

When choosing a fume hood, key factors to evaluate include the specific hazardous materials, chemicals, and dangerous fumes that will be used in the workspace. This will help determine the appropriate hood type, such as a ducted model for direct exhaust or a ductless version with specialized filters. The size and layout of the laboratory space, as well as any local environmental regulations, should also be taken into account. Stainless steel construction may be preferred over other materials for enhanced durability and resistance to corrosion. Additionally, considering the hood’s air velocity, containment capabilities, and overall performance indicators like a magnehelic gauge can ensure the selected unit provides the maximum level of protection for lab personnel working with hazardous substances.